Part 3 of a series on independent archery businesses. This week, Keith Shetler of Earlyhuman.

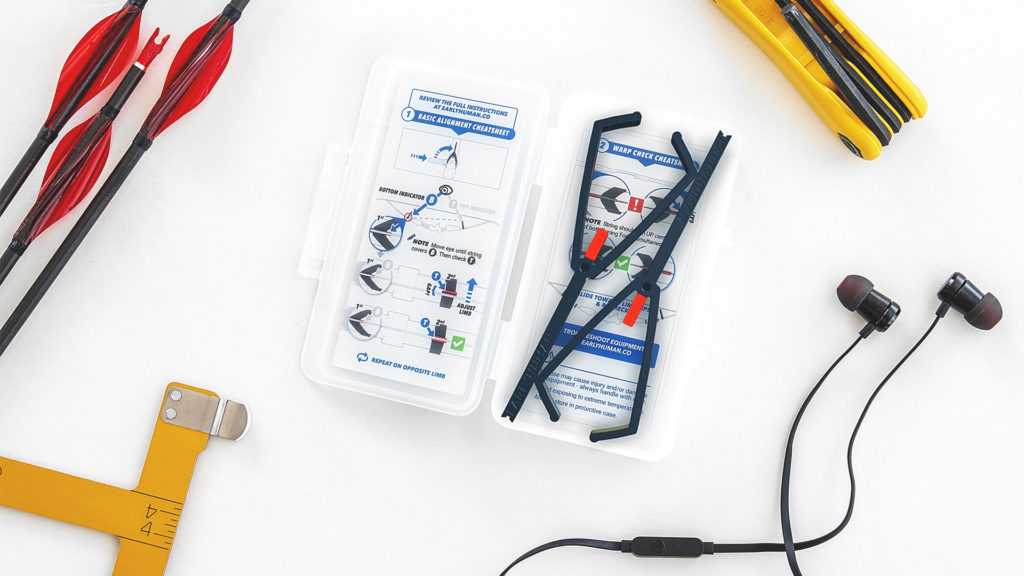

I make Tuning Forks, which are a toolset for helping recurvers align their limbs along a single plane in 3D space — sounds complicated, but the toolset makes it pretty easy to get things right.

It’s called Earlyhuman because archery is one of the oldest human activities. As a species we probably only exist because of archery. As a sport though? We’re really just getting started. There’s so much room to advance understanding and grow the sport. Also, the name reminds me that we’re just all a bunch of kids flinging sticks.

I always hated bow alignment with all the uncertainty and tail-chasing. It seemed like a problem I could solve for myself. After tinkering with ideas, I found out other archers were having the same issues. It never hurts when people offer to pay you for your idea.

I had Tuning Forks prototypes out with several high-level coaches for feedback before I decided to pull the trigger on a Kickstarter campaign. The first campaign failed, but I had enough backers willing to give me money that I took a chance and launched a second campaign. I’ve been selling Tuning Forks on my own site and through other retailers for over a year now. It’s still a small part-time operation – it’s only me and my wife. We’ve only just broken even on manufacturing and material costs, so without paychecks we’re more like volunteers than employees.

I had no experience in manufacturing or running a business for physical products. My day job prepared me somewhat for the business side. But to make a physical consumer product I had to jump into the deep end of the pool and learn product design, 3D printing, injection molding, packaging design. It took a lot of trial and error. It really makes you realise how lucky we are that any product gets made at all, let alone complex items like phones or cars.

Having the ability to dream up an item, then make it real for the benefit of others is the real draw to owning a business. Also, for better or worse, being able to control quality, direction and vision is nice too.

I don’t really advertise. I don’t have the budget for that. And honestly the best advertisement has been word-of-mouth. Having the support of others on ArcheryTalk was huge especially during the Kickstarter campaign. This sport can get caught up in marketing for shiny new things, but when one archer tells another that a product really worked for them… what’s better than that? Especially in such a small community, that completely validates all the blood, sweat and tears put into this.

The hardest part of producing Tuning Forks has always been maintaining quality and utility. I often have unreasonably high expectations of myself. I’m the biggest bottleneck for production since there is a lot of physical prep involved (inspections, cleaning cases, attaching labels, painting markings, etc). I’m working on ways to simplify the process while still maintaining that high quality and utility.

When I hear that other archers find Tuning Forks useful, that gives me the most satisfaction, it drives me to keep going. Also I love when I get direct orders and I’m able to include a “thank you” on each packing slip. I imagine an archer in Arizona, Berlin or Colombia using them and I’m just amazed. If you searched hard enough you’d be able to find a set of Tuning Forks on every continent except Antarctica.

One of the great things about running a micro business is that you can evolve at your own pace. I don’t have any real expenses, no salaries to worry about. I don’t need to release a new thing every year. I can move at my own speed. That said, I have some dreams. Besides some other product ideas I’m developing, I’d love to help bring more financial parity to the women’s side of the sport, collect and release open-source studies on the mechanics of archery, and help grow participants and viewership.

Here, the owner does everything. He is the product designer, is the marketer, is the production line, is the help tech. I think that’s pretty unique for physical products. That’s great for hitting high quality bars, but probably bad for my sanity. And with such a small size, I really can personally thank everyone that orders a product from me.

Have a money-making gig in addition to the archery hustle, at least initially. There’s a reason why archery products aren’t the bread and butter for Easton, Beiter, and W&W. They all make products for different industries with larger markets. Everyone says “I don’t do archery for the money” and at this point that holds true. That said, after talking with various suppliers who’d love some extra business these days, it seems like a really good time to start something new.

My advice? Start as small and as cheaply as possible to meet your goals, test the waters, grow slowly.

Visit earlyhuman.co on the web for more

If you are an independent archery manufacturer with a story to tell and you want to be considered for I Made This, please email the editor.

OK, but I leave in Europe and I have to use this tool, but I can not buy, because I can’t find it in any store.

Is there dtill a chance to order them? But they need to be sent to Germany!