The oldest archery company in the US reaches its centenary in 2022

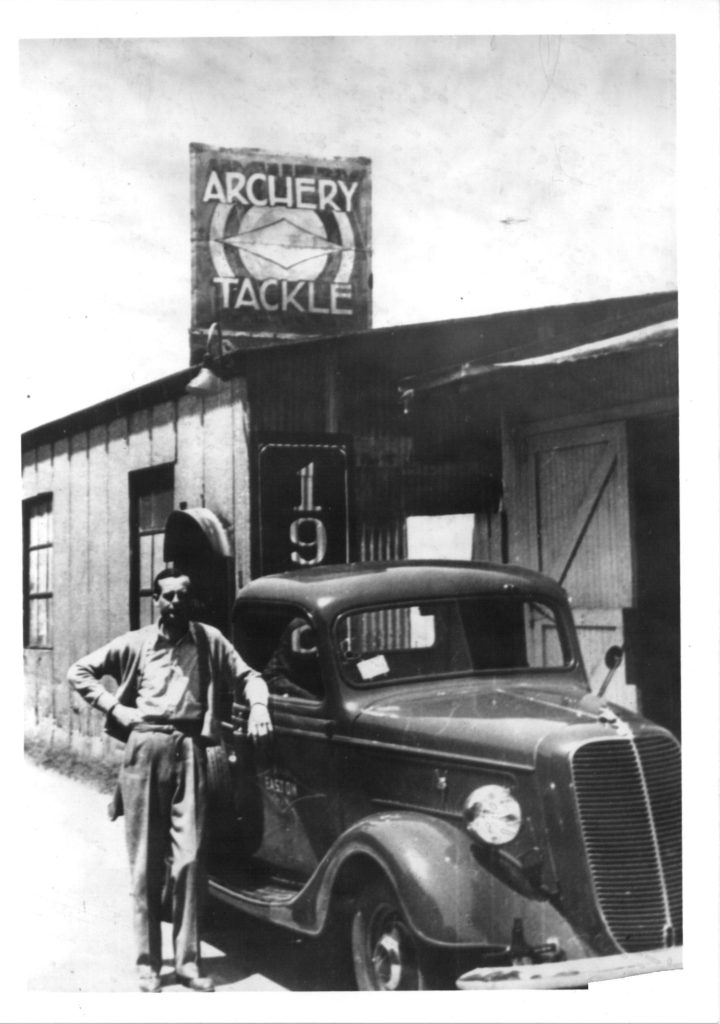

One of the best-known names in the sport, Easton’s archery products are used around the world. It remains a family firm, founded in 1922 by Doug Easton, who began crafting his own bows and making wooden arrows out of cedar and pine. In the 1970s he passed the business to his son, Jim, who in turn passed it to his son Greg Easton, who remains in charge today.

“We’ve always been a family business,” Greg said in February 2022. “It lets you focus on what’s important for the company, not for the shareholders… we’ve never even thought about going public.”

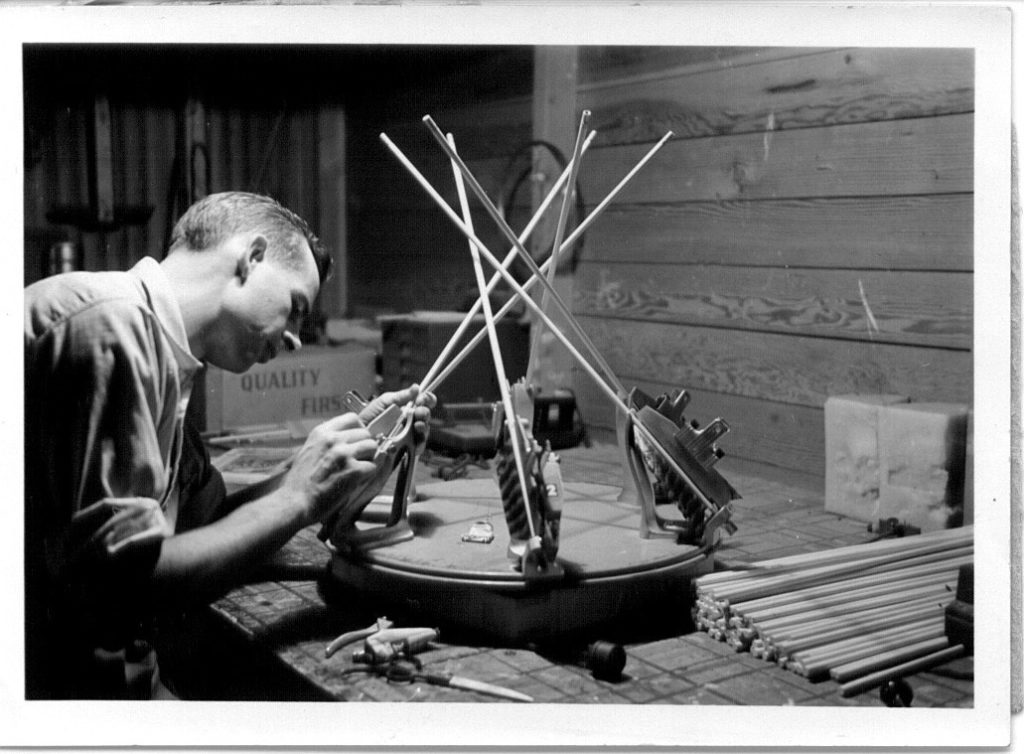

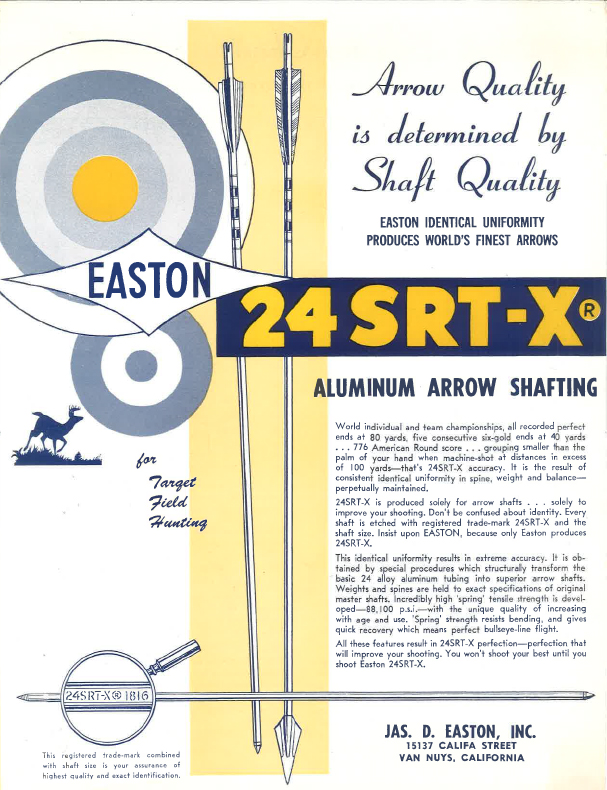

Doug Easton opened his first shop in 1929 in Los Angeles, then the centre of US archery. In 1939 he developed the world’s first aluminium arrow, changing the sport beyond recognition. In 1941, Californian Larry Hughes won the National Championship with a set of Easton aluminium arrows. Tournament scores skyrocketed, along with demand for the products.

In 1958, Easton followed up with the XX75, which became the best-selling arrow shaft of all time. Cold drawn from aircraft grade 7075 alloy to unheard-of tolerances, Easton soon made it available in an unheard-of 22 different sizes – one for archers of every age and stature.

Jim Easton went to work for his father in 1960 and expanded the company to new altitudes with ski pole shafts and, higher still, with the development of the thermal shaft for the seismometer used on the Apollo moon landing. Products in many other fields followed, including baseball and softball bats, aluminium-carbon hockey sticks, and even aluminium drumsticks.

The carbon future

Doug Easton lived to see his arrows used at archery’s return to the Munich Olympics in 1972. He died in December of that year, and his son Jim and his grandson Greg Easton would continue the legacy. They would pioneer the introduction and evolution of aluminium carbon hybrid arrows in the 1980s, the next innovation to dominate the sport, following that with the full-carbon shafts that are the standard today.

One of Easton’s most successful products, particularly in terms of the domination in its field for so long, is the X10 arrow, developed in the mid-90s by Jim Easton and George Tekmitchov specifically for long-distance shooting. Since then, it has been extraordinarily successful, particularly in the context of the Olympics, then as now the pinnacle of the recurve sport. Easton usually runs a wry ad in the wake of every summer Games, pointing out that once again, every archer on the podium used its product.

Tapered shafts have been in use for thousands of years. By tapering and thinning the back of the arrow and keeping the same diameter in the front of the shaft, arrows gain better performance. The tapered shape reduces drag while producing a higher front-of-centre balance.

Fully barrelled shafts – where the front half tapers to a point, creating three distinct ‘zones’ on the arrow – also date from antiquity. But barrelled arrows until very recently were custom made, one-off sets. Jim Easton experimented for decades, but it took many years for the technology to catch up to the point where barrelled arrows could be manufactured to the tolerances required for top-level archery.

The difficulty in manufacturing is one of the reasons for the high costs involved, certainly compared with manufacturing parallel shafts. This is because each spine requires a separate approach, custom materials, shape and flex pattern.

The X10 followed on from the barrelled A/C/E, which was introduced in 1987 and used by Jay Barrs to win the 1988 Olympic Games. The X10 was released in 1995 and since then has won every Olympic Games gold medal. It has also set every outdoor world record achieved since then. It is fairly extraordinary to a single product to dominate this long unchanged.

Why it works

The smaller diameter of the X10 shaft presents less surface area and a smaller cross-section to the wind. More importantly, the X10 has a high ballistic coefficient – it correctly balances mass weight and momentum for better performance from recurve bows at longer distances, especially in windy conditions.

In earlier times, the X10 was shot by compound archers with the rearward taper portion partly removed to stiffen up the arrow – compound archers do not benefit from a rear taper that assists in clearance and makes finger releases more forgiving.

The experiences with compounders using the X10 lead to the development of the Easton X10 Protour arrow.

Easton is celebrating the anniversary with a book detailing the history of the company, along with a small touring exhibition that appeared at the Vegas Shoot. This year, Easton is releasing the new Superdrive Micro all-carbon shaft as a do-it-all arrow for multiple uses and bowstyles, among several other products. The future seems assured.