Recurve engineer George Tekmitchov looks at the development of string materials, and how to get the best out of yours

The bowstring is one of the three fundamental components of any modern recurve bow. Limbs, riser, and the string are all named in the World Archery rulebook as the fundamental components defining the bow. Without its string, a bow is useless.

Your bowstring can have a profound impact on many aspects of shooting, from tuning and grouping, to noise and vibration. With new string materials constantly being developed, it can be difficult for shooters to determine their best choices. In this article, I want to take a closer look at bowstring materials and methods to help cut through the confusion.

Material

Competitive archers have seen more progress in the past 50 years than in the past several hundred years when it comes to bowstring material technology. Waxed linen strings dominated our sport in the west for more than 600 years, right up through the 1950s. Other materials found in use across the globe include horsehair, cotton, catgut, silk, and Chinese grass fibre.

In the later 1950s and early 1960s the explosion of synthetics quickly displaced traditional linen and similar natural materials. One of the first of these, still in some use today (mostly on beginner bows), was Dacron polyester. In the 1970s and early 80s, in high-level target archery, non-stretch Kevlar strings displaced Dacron. These materials had many advantages over natural materials. They were proofed against moisture, more forgiving of large temperature swings, and more durable (in the case of Dacron).

However, some of these also had serious disadvantages, compared to modern Spectra- or Dyneema-based string materials. Dacron will continually stretch and change over time, while Kevlar will always, eventually, unexpectedly break, often in the course of a competition. Spectra/Dyneema based materials changed all of that. In fact, when the Hoyt Archery Company introduced Allied Signal Spectra fibre string material to the archery industry in the mid 1980s, it proved to be one of the biggest single performance leaps in recurve archery in the past 30 years.

Spectra and Dyneema are both, technically, Ultra High Modulus Polyethylene (UHMPE) fibre. There are some small differences between the two materials, but they are, for the most part, physically similar. Practically impervious to solvents, normal environmental conditions and moisture, the weak point with these materials comes into play only at greatly elevated temperatures, well beyond what one can expect to encounter in the course of a competition. Under tension and in high temperatures these materials will exhibit “creep” and stretch.

Blends

In the mid 1990s the “creep” characteristic of some UHMPE strings and compound cables led to the development of blended fibres using UHMPE and Vectran, a liquid-crystal polymer related to Kevlar. The blend helped arrest creep, until the gradual failure of the Vectran component in the string or cable would manifest itself. With good maintenance and improved string waxes, these issues can be managed. However, many shooters feel these materials are too harsh in terms of shot reaction. Accomplished shooters who choose to use these materials typically run reasonably high string twist counts to compensate for the “abrupt” feel from these materials. As the blending processes for these materials has improved however, a somewhat larger number of shooters have gravitated to these materials. For longest string life, silicone-based synthetic waxes are recommended for these materials.

Construction

Even the very finest string materials can be wasted, if certain elements of string construction are overlooked. Well-constructed bowstrings feature a number of key features that enhance performance, durability, and reduce variability over time. One of the most important of these is the consistency of strand tension during construction. Incorrect or uneven individual strand tension can cause the string to change in unpredictable ways, especially when going from cool to warm conditions. Incorrectly tensioned strands can even cause an imbalance that can cause the string to load at different rates from shot to shot, resulting in grouping difficulty. One trick you can use to help ensure your string is going to have good strand tension distribution (assuming only minor differences) is to take all twists out of the string, string your bow (yes, the brace height will be low) and simply let it sit overnight. This will force the tighter strands to stretch a little and allow the looser strands to take up their share of the load. When re-twisting to achieve correct brace height, be sure to twist in the direction that tightens the centre serving. You can determine this immediately simply by grasping each end of the served area between thumb and forefinger, and twisting. One direction will be harder than the other. Twist into this direction.

Twist rate (twists per unit length) can have a significant impact on string behaviour. If you don’t have enough twists in your string, the string can be noisier, and possibly less consistent in terms of maintaining brace height if the strands aren’t loaded evenly.

On the other hand, too many twists may reduce performance by absorbing energy and behaving a bit like a rubber band. With that said, modern strings can work well with a fairly wide range of twists. For example, on a string for a 68” bow, anywhere from 20-60 twists will produce acceptable results as long as the bow’s brace height (string height) is correct. Generally, more twists will slow the bow slightly and produce much less noise, while fewer twists will add a tiny bit of speed, but potentially more noise.

Serving Materials

Serving materials are another important and integral part of the bowstring. However, servings have two very different functions on the bowstring. The end-loop servings must be abrasion resistant, but not abrasive themselves, so as to avoid damage to limb tips and underlying strands.

End-loop serving should be low in mass, and must tightly grip the underlying string strands to prevent any instances of separations, loosening or fraying.

On the other hand, the centre serving has multiple functions with potentially different requirements than those of the end loop materials. Centre servings must provide for a smooth and consistent release from the shooting tab surface, and also resist separation and loosening to prevent the nocking point from changing. They must also often be called upon to resist wear from brushing the armguard after the shot. Finally, they must keep their diameter over a long period of time, so as to prevent a change in nock fit.

Certainly, there are a number of materials which function well as serving for a recurve string, with the original Angel braided material (and the similar BCY Halo) still excellent choices for centre servings, and material blends of Spectra/Dyneema and polyester such as Brownell Diamondback are popular end loop material choices. Interestingly, however, extensive testing shows that Angel Majesty serving material is actually the best material for both of these applications, due to a unique combination of smoothness and tenacious locking ability on the underlying string strands.

Strand effect on tuning

It’s a simple matter to say that strings with more strands are slower and less strands are faster, but the fact is when we change the number of strands in a string, we change more than one variable. For instance, a smaller diameter (less strand count) string also generally has a looser nock fit (if not compensated for). This can cause big changes in tuning, even beyond the effect of the strand count change. Obviously a strand count increase can cause the opposite effect. Experienced shooters are careful to account for this by using a larger or smaller size throat nocks, or by using larger or smaller serving diameter, to achieve a predictable and correct nock tension. Generally, nock tension should be set to allow an arrow to hang off a strung bow with the string held parallel with the ground, but not so tight that the arrow can’t be dislodged with a sharp tap on the string.

Nocking points, kisser buttons

It’s not always obvious, but a small change in string mass at the centre can have a lot more of an impact than a larger change distributed over the entire string. In fact, adding 10 grains to the centre of the string has about five times the effect of adding 10 grains to the overall string. So, we need to choose accessories such as nocking points and kisser buttons with a bit of care, and at least be sure to have these in place as you progress with tuning, since adding them afterwards can cause a substantial change.

Maintenance (or, better bowstrings through chemistry)

“Wax is to an archer what tar is to a sailor; use it often, and always have two strings to your bow.” Excerpt from: Saxton Pope, Hunting with the Bow and Arrow.

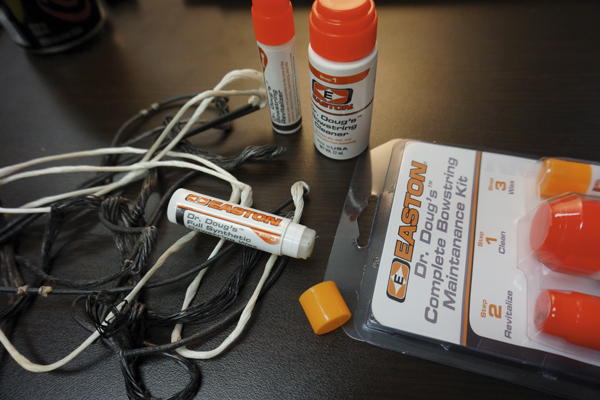

Modern strings are well served by at least some maintenance. In some ways, especially for more traditional bows, it’s hard to beat one of my favorites, natural beeswax. But for more modern string materials, particularly the Vectran blended materials, string lifespans can be dramatically improved by using more modern, synthetic waxes. You can even take it to the extreme of a total string maintenance kit, consisting of cleaners, restoratives and waxes. A number of manufacturers offer these total maintenance kits, including Easton. You can also visit the Easton YouTube channel to see how to use this (or any) string kit and pick up a few tricks of the trade.

The Easton “Dr. Doug’s Complete Bowstring Maintenance Kit” features a cleaner, revitaliser and wax to restore and protect strings and compound cables

Conclusion

If you have come into archery in the past 25 years, you may not remember the “bad old days” of Kevlar and Dacron. Very few archery-related items have made as much progress as string materials have in the modern era. But, even as good as modern materials are, accidents can happen. And, any bow is useless without a good bowstring. So, most competitors always maintain at least two well-used strings, ready to go and interchangeable on any given bow. For a competitive archer, this is really very inexpensive insurance for your competition performance.

When you state the old theme that more strands in a string make it slower, which has been said for 20 plus years to my knowledge, this is no longer always correct.

I am obtaining 196ft per second from from my win win 68″ recurve bow with just

37 lbs on the fingers. This figure is higher than all the other 150 archers in my club and i shoot a 20 strand string.

Hey Derek,

I think in your answer their is a misunderstanding. Concerning the numbers of strands you have to distinguish which typ of string yarn you use. String yarn ared different in thickness. For Example BCY 8125G, BCY452X have another thickness as BCY8190 or BCY X. So for the first called two yarn types you normally use 16 -18 strands compare to the last called two types you have to use 20 – 22 strands (for recurve bows).

It seems in your case you use either BCY 8190, BCY X or Trophy.

kd rgs

Congratulation on this report. In my opion ther contents should be completed.

1) Spectra and Dyneema

Spectra is the name of the yarn HMPE yarn type, which was produced by Allied Signal under license by DSM Netherlands to have a certain technical solution (the most important target was not to find a better for bow strings).

To the time explained in this report Brownell developed the string yarn FastFleight based on the Spectra yarn. At beginning of 1990 a further suplier of bow string yarn entered the marked:BCY. They offdered the same yarn types but change the name as Dynaflight.

In the last 35 years uto now DSM Netherlands made five steps to increase competition of their yarn types so in this relation the bow string yarn follow this developement.

The brand new developement of bow string yarn offers the German Suplier Lippmann Bow String, D- Hamburg ( http://www.lippmannbowstring.de ) which enter the market in 2013 with the new string yarn typ Lippmann XTX. The bow string yarn is named LBS SUPERB based on 100% HMPE DSM Dyneema in a complete new polymer structure to avoid creep. Compare to the USA-Supplier it is not necessary to blend this yarn with vectran how it Brownell and BCY do for BCY452x, BCY X, Trophy.

Dyneema is only the label uses from DSM Netherlands for their diffderent HMPE Yarn types.

kd.rgds.